Aerosols play a very important role in maintenance of any type of industry since it is convenient and easy to use. The propellant is the heart of aerosols. By the end of this article, we would understand the answer to How ?

Aerosols are only different type of packaging i.e they are pressurised dosage forms containing one or more active ingredients (product concentrate + propellant) which upon actuation emit a fine dispersion of product concentrate in a gaseous medium.

This is where a propellant comes into action.

What Is A Propellant?

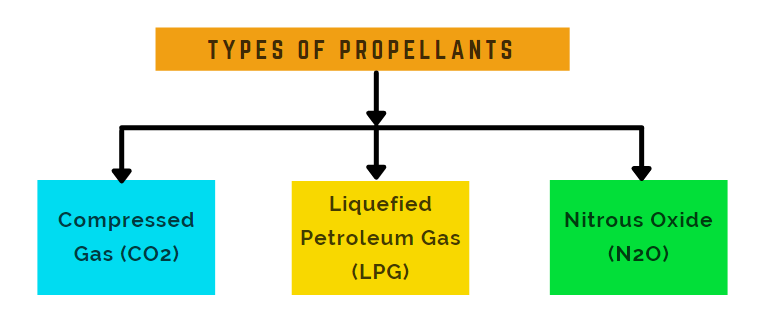

A propellant is a substance used in the form of pressurized gas for production of energy that is subsequently used to create movement of fluid. There are many types of propellants which can be used to create pressure inside the tin.

How Aerosol Tin Works?

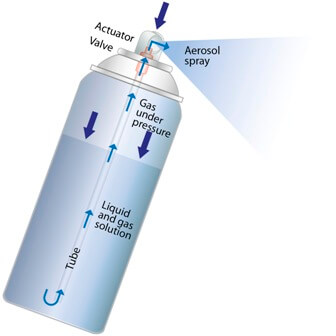

- We press the nozzle, forcing the air to move outside

- The release of air causes the sudden drop in air pressure inside the tin

- The air inside the top of the tin is at higher pressure than air in the tube, so it pushes down on the product concentrate

- The product concentrate is than forced up the tube towards the mechanism for release

- The product concentrate than leaves the tin in the form of spray

The most common types of propellants used are CO2 and LPG. We will understand the propellant in detail for better understanding and usage of the same.

Carbon Dioxide (Co2) Propellant

Carbon dioxide is the ideal gas because it comes from natural gas. It is easily available in underground sources.

Pros

- Non – flammable

- Non – explosive

- Non – combustible

Cons

- It is incompatible in an aerosol tin with water or traces of water

Liquefied Petroleum Gas (LPG) Propellant

Liquefied petroleum gas is a blend of two flammable but non – toxic gases propane and butane and it is very convenient and super pressurized gas used in aerosol tins

Pros

- Easily available

- Economical

- Good solubility with products

Cons

- Flash point is approx – 58°CExtremely

- Flammable

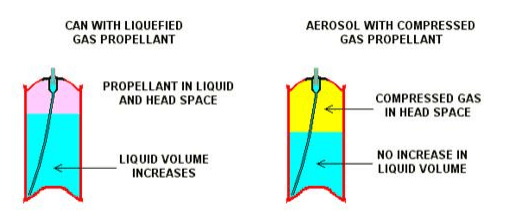

Aerosol with LPG as a propellant have relatively less qty of product concentrate and more of LPG gas. But have constant pressure throughout the service life of tin

Comparative table between the most used propellants

Liquefied Propellants

1. An integral part of the formula results in smaller, finer particles

2. Consistent Pressure through life of can.

3. Large temperature changes affects pressure

4. Cost varies

Compressed Gas Propellants

1. Acts like piston contains large, wet particles (however there is some solubility with Co2 )

2. Drop in pressure through life of can

3. Temperature changes have little effects on pressure

4. Low cost

We will try to solve the mystery behind consistent and inconsistent pressure with LPG and CO2 propellant

LPG is a liquefied petroleum gas i.e it exists in two-phase gaseous as well as liquid. Under high pressure, gas is in a liquified state. When we spray, some amount of gas is released with the product concentrate and some part of the liquid LPG changes into gas to fill the void space created. Thus maintaining the constant pressure throughout the service life of the can.

CO2 is carbon dioxide and exits in a gaseous state. When we spray, some amount of gas is released with the product concentrate. With every spray, some part of the gas is released thus reducing the pressure of the aerosol can in its service life.

Nitrous Oxide (N2O)

Nitrous oxide is commonly known as laughing gas. But is not widely used in the lubricant industry. It is widely used in the pharmaceutical industry because of its property of slowing down the body’s reaction and functions as a mild sedative.

Propellants are used based on the applications. MOSIL has a wide range of products under different categories which cater to the specific needs of the client as per requirement. One can visit MOSIL website (www.mosil.com) for further information and raise an enquiry.

![The Ultimate Guide To Grease Thickeners [Thickening Agents]](https://mosil.com/assets/uploads/blog/blog_1754991852_689b0cec60a8a.jpg)

![Gear Drive Lubricant Selection [Gearbox Lubricants]](https://mosil.com/assets/uploads/blog/blog_1754993108_689b11d41226a.webp)