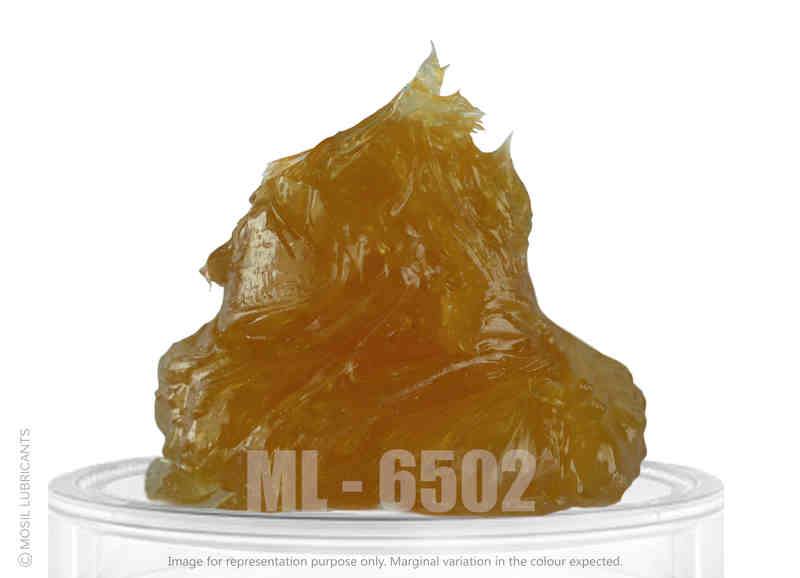

ML - 6502 | Heavy Duty Grease

A Specialty EP grease formulated with high viscosity base oil and sophisticated additive package providing unparalleled protection under dynamic load conditions. Its proprietary EP additives provide superior protection and performance in shock loading applications where conventional greases damage the component due to rupturing of the oil film.