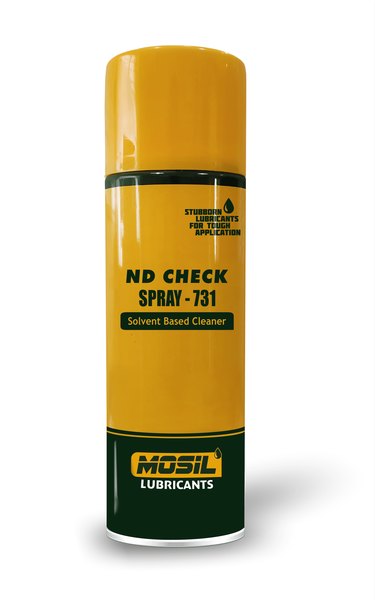

ND CHECK - 731 | Solvent Based Cleaner

It is a Solvent based Cleaner sprays used in a process of LPI/DPI (Liquid / Dye penetrant inspection) the make sure the component which is to be clean is free from any kind of impurities and contamination. It removes and cleans all type of dirt, oil, grease or any loose scale from the test surface so that the surface is well prepared for LPI and it will not cause irrelevant or false indications due improper surface preparation.