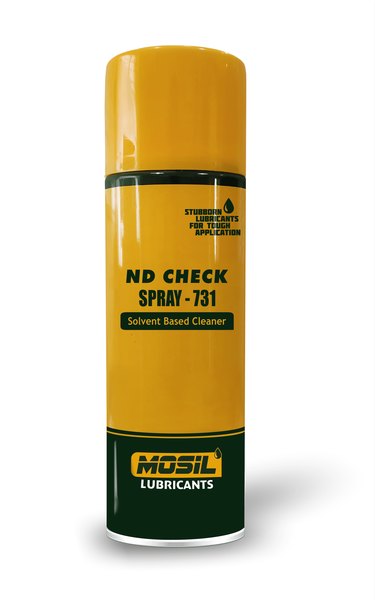

ND CHECK - 732 | Solvent Removable Visible Dye Penetrant

It is a solvent removable Penetrant used in a process Of LPI/DPI (Liquid / Dye penetrant inspection for identification and detection of hairline cracks, porosity and discontinuities on the surface of a nonporous material. This is a combination of carefully selected hydrocarbon and diluents with high surface wetting characteristics which allows the liquid to penetrates into the surface-breaking discontinuities via capillary action.