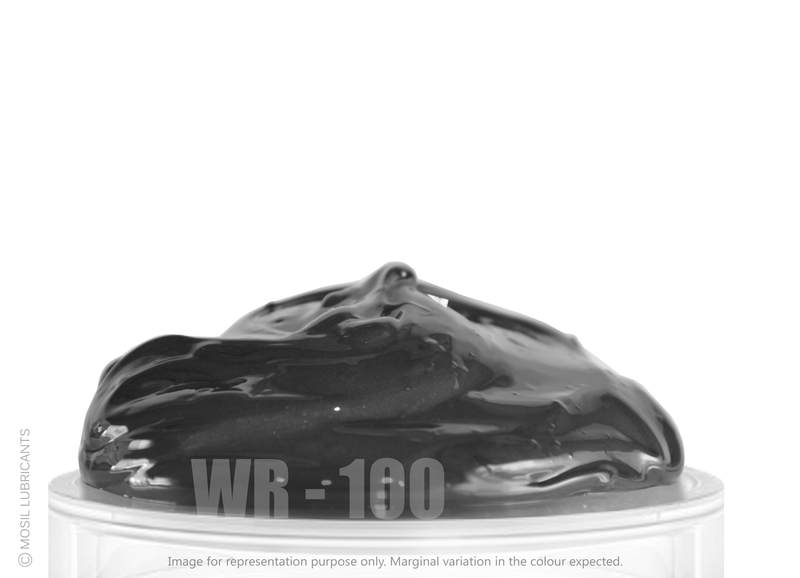

WR - 100 | Wire Rope Lubricant

It is heavy duty wire rope fluid with high quality lubricating solids such as Molybdenum disulphide to provide high antiwear and load carrying capacity. It is blended with additives such as rust and corrosion inhibitors and anti-oxidants to provide rust protection and oxidation stability for high temperature and heavy duty applications. Mosil WR – 100 penetrates the surface of the rope quickly and efficiently to provide effective lubrication of inner strands. The boundary lubrication provided by Molybdenum reduces the strand wear thereby extending the rope life.