Ever heard, “Toxic people pollute everything around them", this is also true with lubricants.

Being in a bad surrounding can cause devastating effect on industrial lubricants, both in terms of quality and life. It is important to identify the bad environment and take necessary steps to avoid lubricant from getting affected. In this blog we will get a general idea regarding lube oil, its degradation, preventive measure, features of MOSIL’s lube etc.

It is a lubricant which is used to reduce friction, wear, generation of heat due to contact between mechanical components.

All of us are aware, that every product which is brought in use has certain life, up to which it can perform its intended function and after that it starts degrading. However, this degradation can be prevented. In order to prevent it, the reasons that cause degradation needs to be studied.

Let us discuss below, different types of degradation of oil.

What are the factors causing lube oil to degrade faster ?

- Oxidation

- Thermal breakdown

- Micro dieseling

- Additive depletion

These are the factors that causes degradation of oil. To understand better let us explain you in detail below.

1. Oxidation

Oxidation occur due to two main reasons:

- Oxygen

- Heat

Problem occurs when these atoms get separated. When these separated oxygen atoms come in contact with unsaturated hydrocarbon oil, it results in further degradation of oil.

During this reaction certain acids are formed which also contribute in degradation of oil. Finally a good lubricating oil starts turning to a bad oil.

Heat can be generated from various sources such as metal to metal contact occurred due to improper lubrication, surrounding conditions etc. Separation of atoms and hydrocarbon occurs due to heat energy.

2. Thermal breakdown

According to Arrhenius rate rule for temperature , For every increase of 10 deg C for oil, the life of oil is cut to half. So its necessary to keep the oil as cool as possible , which may lead to increased life and reduction in thermal breakdown.

3. Micro- dieseling

Temperature greater than 200 deg c is required to initiate the thermal failure, this temperature can be generated due to compressive pressure of 250 psi generated during operations.

Basically thermal degradation of oil occurs in absence of significant amount of oxygen, as a result we will see different products formed due to reaction in both case (Oxidation & Thermal degradation).

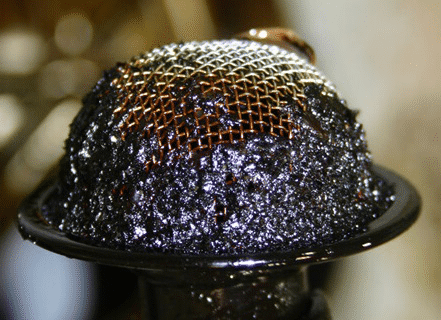

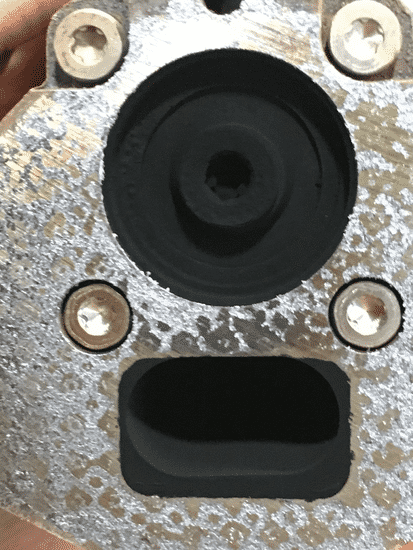

4. Contamination

Surrounding dirt, dust when comes in contact with lube oil, along with it some metal particles can also get added. These foreign particles behave as a catalyst that speeds the degradation process of lubricants. Introduction of oxygen through any means such as water ingress can lead to oxidation of oil.

Conclusion

If the lubricants are healthy, they keep the machine healthy. So selection of proper lubricants for efficient working of machinery is very important. One can easily notice abnormal behaviour of machine by noticing in noise, temperature, vibration.

Even after changing/ improving lubricant, if same condition exists, it now time to turn towards experts who provide lubrication based on application condition. MOSIL lubricants are experts in Specialty Lubricants and provide the best lubricants for your machine.

![The Ultimate Guide To Grease Thickeners [Thickening Agents]](https://mosil.com/assets/uploads/blog/blog_1754991852_689b0cec60a8a.jpg)

![Gear Drive Lubricant Selection [Gearbox Lubricants]](https://mosil.com/assets/uploads/blog/blog_1754993108_689b11d41226a.webp)